PLASTIC SLATS FOR COMBI-FLOOR

Plastic gratings must be able to withstand a significant pressure when they are in use. Therefore, it is important for us to comply with the necessary quality requirements for our products. For our plastic gratings, we perform design validation and quality control by using Finite Element Analysis.

Here is the example of quality test for our 60x40 cm plastic slats for weaners and sows.

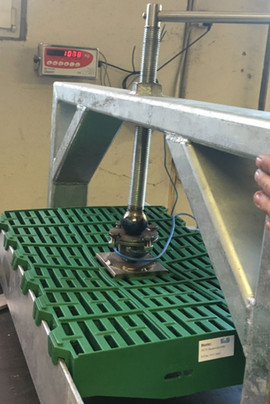

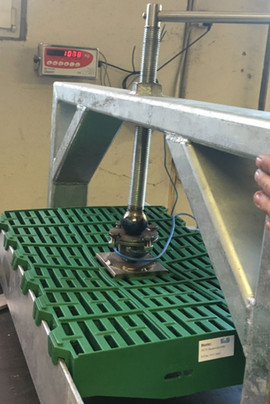

TEST METHODS:

1. Pressure test

- The test is made with a stamp 100 x 100 mm.

- The weaner grating must resist 4,5KN (450kg).

- The sow grating must resist 10,5KN (1050kg).

The test has proved that the plastic gratings are able to withstand the load of 4500 N for weaner slats and 10500 N for sow slats.

2. Impact test:

- 5 kg ball is dropped down to the same spot three times. The ball has to touch the grating only once.

- For weaner gratings, the drop height is 0,3 m.

- For sow gratings, the drop height is 0,4 m.

- Test positions are in the middle and in each corner of the grating.

All gratings have shown great resistance to both pressure and impact tests, proving the high quality of the materials and construction durability.

Plastic gratings must be able to withstand a significant pressure when they are in use. Therefore, it is important for us to comply with the necessary quality requirements for our products. For our plastic gratings, we perform design validation and quality control by using Finite Element Analysis.

Here is the example of quality test for our 60x40 cm plastic slats for weaners and sows.

TEST METHODS:

1. Pressure test

- The test is made with a stamp 100 x 100 mm.

- The weaner grating must resist 4,5KN (450kg).

- The sow grating must resist 10,5KN (1050kg).

The test has proved that the plastic gratings are able to withstand the load of 4500 N for weaner slats and 10500 N for sow slats.

2. Impact test:

- 5 kg ball is dropped down to the same spot three times. The ball has to touch the grating only once.

- For weaner gratings, the drop height is 0,3 m.

- For sow gratings, the drop height is 0,4 m.

- Test positions are in the middle and in each corner of the grating.

All gratings have shown great resistance to both pressure and impact tests, proving the high quality of the materials and construction durability.